Usoro ziri ezi na ọkpọkọ ígwè-Hexagonal

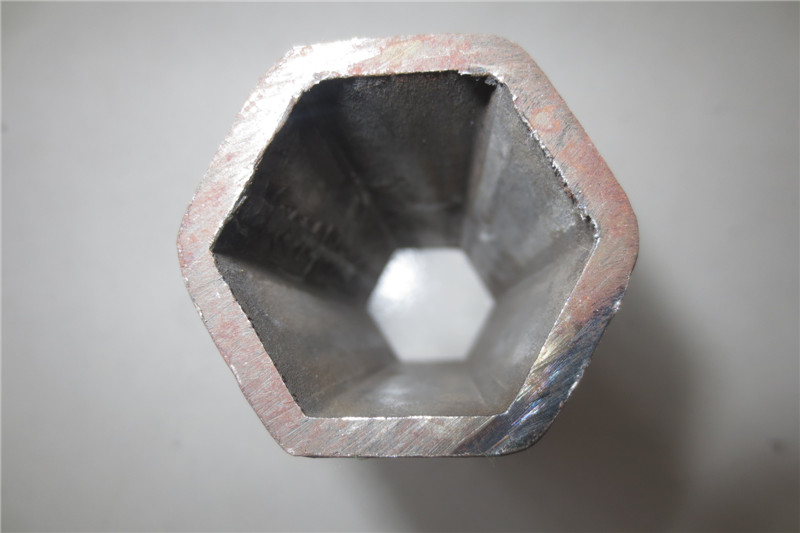

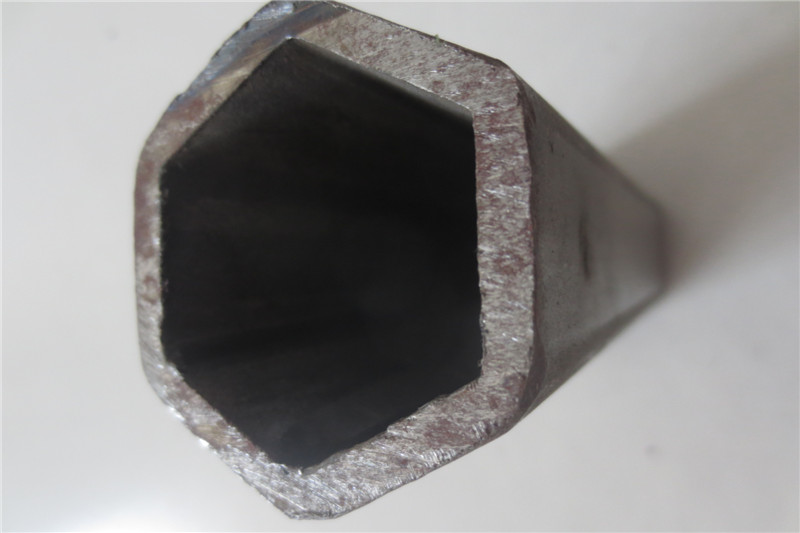

Hexagonal Steel Tube Suppliersbụ a hexagonal (hexagonal ígwè ọkpọkọ), nke a makwaara dị ka ọkpọkọ ígwè pụrụ iche, nke a na-ejikarị eme ihe n'akụkụ dị iche iche, ngwá ọrụ na akụkụ ígwè ọrụ.E jiri ya tụnyere tube gburugburu, igwe anaghị agba nchara pụrụ iche tube n'ozuzu nwere nnukwu oge nke inertia na akụkụ modulus, nwere nnukwu ekwe na nguzogide torsional, nwere ike belata ịdị arọ nke ihe owuwu ahụ, chekwaa ígwè.

Dee ozi gị ebe a ziga anyị ya